- The filter body is St-37 or stainless-steel optionality

- The filtering in pressured lines

- High performance during the back washing

- Extensive Filtering Surface

- Easy-to assembly and fitler components, not required to change

- 100% back washing performance

- The back washing time for 50-30 sec.

- Working opportunity, not required additional energy

- The minimum head and water loss

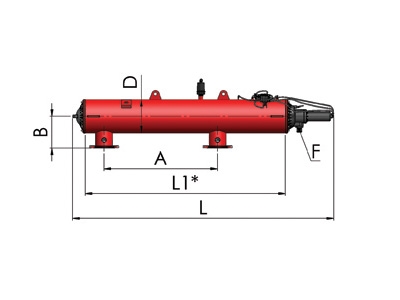

|

| HDF-104 |

4" |

100 |

500 |

287 |

1040 |

1550 |

10” |

120 |

2634 |

87 |

| HDF-104S |

4" |

100 |

600 |

287 |

1240 |

1750 |

10” |

140 |

3951 |

92 |

| HDF-105 |

5" |

125 |

600 |

287 |

1240 |

1750 |

10” |

150 |

3951 |

94 |

| VDF-105S |

5" |

125 |

900 |

287 |

1550 |

2060 |

10” |

160 |

5268 |

127 |

| HDF-106 |

6" |

150 |

900 |

287 |

1550 |

2060 |

10” |

180 |

5268 |

131 |

| VDF-126S |

6" |

150 |

1100 |

312 |

1942 |

2442 |

12” |

220 |

7902 |

147 |

| HDF-128 |

8" |

200 |

1100 |

312 |

1942 |

2442 |

12” |

320 |

7902 |

151 |

| VDF-1210 |

10" |

250 |

1100 |

312 |

1942 |

2442 |

12” |

380 |

7902 |

161 |

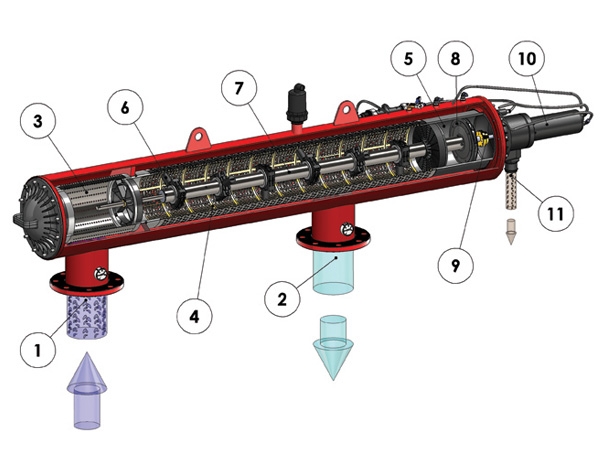

Water, entered from input collector, puts particules, contained by itself, in rough screen (3) and passes to part which include multiplex filter (3). It is protected with a rough material with screen over of multiplex screen. The thin filter goes to output collector side (4). Particles, collected on multiplex screen, constitute a pollution layer over of the filter and a pressure difference in the outsite collector. This pressure difference open a back flushing unit washing decharge valve (10) in the value, designed previously (12) and a powerful back flushing flow consists from decharge pipet o atmosphere (11). This flow cleans the particle layyer, collected on filter by creating a vacuum from holes over of nozzle (6).

The dirty water, absorbed on multiplex filter, creates real volution by passing from water cleaning nozzle pipe (7) and hydrolic turbine (8). The pressure loss, consisted of turbine container (4) and plunger dreinage (9) constitutes an axial movement. The spiral headway, constituted by this axial and volution together, obtains the absorbing whole filter surface by vacuum nozzles.

When this process is done, the cleaning collector makes a second back flushing with warns with its warning switches and turns its first position. Transaction is completed.

During the back washing, the filtration process contiunes and after the back washing process, the filter stands by until next pressure difference signal.