Frequently Asked Questions

Spraying water at a certain angle and pressure, and then letting it fall by its own weight in tiny droplets on the soil and product is called “Sprinkler Irrigation”. This method is called sprinkler irrigation, because the water looks like the natural rain. Sprinkle irrigation can be used in any soil condition, on slopes, flat lands, and almost on any types of plants conveniently. Water with a lower flow rate in comparison to the flow rate surface irrigation requires can be used. Water is sprayed through the nozzles at a certain pressure and released to the atmosphere just like it rains normally. Water, dropped on the ground penetrates into the soil and accumulated around the root of the plant. In sprinkler irrigation, water comes to the nozzles at a certain pressure, and falls on the ground as an artificial rain.

A water installation consisted of a main pipe and lateral lines and a water pump generating the necessary pressure are required for using this method. The pressure is usually generated by a pump unit. Self-pressurized systems called closed circuit are available in some regions. Sprinkler heads identify the system. There are different types of sprinkler heads, depending on the plant, soil, and financial issues.

Sprinkler irrigation systems need less irrigation water than surface irrigation systems,if they are operated properly. They are more useful especially on rough lands with slopes, and higher penetration rates for irrigating plants with shallow roots.

Sprinkler irrigation method requires a certain amount of initial investment and energy costs. Sprinkler irrigation systems will develop, if using this method provides an increase in the number of agricultural products that compensates such costs. Sprinkler irrigation methods are widely preferred, where labor is expensive, because they require less labor.

Portable Systems

Pump unit, main pipe and laterals are portable in this system.

Semi Portable Systems

Pump unit and main pipeline are fixed, and laterals are portable in this system.

Non-portable (Fixed) Systems

Pump, main pipe, and laterals are fixed in this system.

Sprinkler irrigation methods are widely preferred, where labor is expensive, because they require less labor. Semi-portable and fully fixed systems are preferred more and more in nowadays, because labor costs are constantly increasing.

Main components such as pipelines, and sprinkler heads of sprinkler irrigation systems have been significantly changed recently. The cost has been lowered, and the system has become practical thus, their use is generalized. Sprinkler heads are of greatest importance in sprinkler irrigation system. High capacity sprinkler heads (Big Guns) with high wetting capacity are widely preferred. These are very good at medium and high operating pressures. Low pressure applications may damage delicate plants. Nozzle diameters of medium size sprinkler heads are ranged between 8 to 12mm, and their wetting diameters between 15 to 25 mm. Such heads are widely used in the irrigation of field crops, vegetable gardens and orchards. Nozzle diameters of large size sprinkler heads can be ranged between 12 to 28mm, and wetting diameter between 25 to 55mm. Such heads are mainly used in the irrigation of field crops by medium and large sized enterprises.

Operating pressure is the pressure required at the nozzle. Losses due to leakage and friction can be controlled by calculating the pressure differences between the manometers at the pump outlet and the distant sprinkler head. Valves can be installed at the beginnings of lateral pipelines, in systems the main pipelines, of which are embedded in the ground. In addition to these, connection pieces such as T, bend, reduction, and pipe stopper are also used. Saving energy or using more sprinkler heads with the same energy is possible by using pipes with the largest possible diameters, minimizing friction loss.

The information needed for designing sprinkler irrigation projects:

- Field moisture capacity

Plants use the water, the quantity of which is ranged between the field moisture capacity and permanent wilting point, available in soil. This moisture is called “field moisture capacity” or “useful capacity”. This depends on the nature of the soil. Soil analysis and infiltration tests are required for once. The data obtained can be used for years unless the properties of the soil are changed. - Effective Rooting Depth of Plants

The depth of rooting at which plants extract 80% of the water they require for normal development is called “Effective Rooting Depth”. This figure usually within the range of 30 to 180cm gives the depth to be charged by the irrigation, depending on the type of plant.

- Irrigation water needed for crops

Water consumption of plants is low at the beginning of the growth season. It gradually grows towards the maximum surface soil level, and reaches at its maximum. Thus, plants are irrigated less frequently at the beginning, and more frequently when the water consumption is at maximum. Sprinkler irrigation projects are designed considering the highest water consumption of the plant. There are many methods used for determining plant water consumption. - Soil Water Intake (Infiltration) Rates

Knowing soil infiltration rates is important in irrigation. The rate of infiltration is affected by soil characteristics, quantity of organic materials, moisture, vegetation cover, slope, irrigation method used, firming and cracking, and type sand quantities of minerals. Cylindrical in filtrometer sare used for calculating soil water in take rate through in filtration tests. The figure obtained is very important in determining the suitable sprinkler head and nozzle.

Advantages of Sprinkler Irrigation

- Efficient use of water. Water is utilized highly at places where irrigation water supplies are low.

- Irrigation can be possible on sloped land types with irregular shapes (topography) without causing erosion.

- Eliminates the condition, in which due to soil formation the plant cannot reach to soil surface during germination period.

- Economized operating expenses and labor.

- The most suitable irrigation for shallow, permeable soil with low depth.

- Salt particles carried by the wind and accumulated on the plants at sea sides, dust and harmful insects can be washed off by sprinkler irrigation.

- The most suitable irrigation type, where water table is high and drainage is a problem, as the water flow can be controlled in sprinkler irrigation.

- There is no need for field ditches thus, the number agricultural areas are increased, and agricultural enterprises are easily operated.

- Soluble artificial fertilizers can be delivered to plants with irrigation water, no need for any labor.

- Eliminates field contouring expenses thus, provides saving in time and energy.

Disadvantages:

- Initial cost is high especially for fixed systems.

- Winds have negative effects on water distribution. Irrigation should be preferably carried on early in the morning or at around sunset time, when it is less windy.

- Pressure requires power. This means spending energy, and expense.

- Learning the advantages of using sprinkler irrigation makes it more and more preferable.

- The main pipe should be parallel to the slope

- Sprinkler laterals should be perpendicular to the slope but parallel to the contours if possible

- Laterals should be placed perpendicular to the wind direction, where the speed of the wind is high

- Avoid using too long sprinkler laterals. Shorter laterals reduce labor and provide an even water distribution.

- The motion of the laterals should be arranged on the main line in a way that requires minimum labor.

- If possible, the system should be installed in square or rectangular form ensuring easy lateral motion and lower number of collaborative heads to be changed.

- Pipe sizes and arrangement of a system, should be in a way to reduce annual costs.

- If possible, pump unit should be installed in the middle of the system; this enables using economic pipes with appropriate diameters.

- In sprinkler irrigation water is efficiently used, where there is water shortage.

Commercial fertilizers can be carried by water delivered to plants by sprinkler irrigation. Delivering fertilizers carried by irrigation water to soil provides various advantages.

Including:

- Less labor

- Homogenous distribution of fertilizers in soil

- Extends the useful economic life of tools and equipment

- Optimum fertilization in optimum time

- Increase in product quality and quantity

Commercial fertilizers can be carried by water delivered to plants by sprinkler irrigation.

Irrigation continues after the fertilizers have been ejected, thus the fertilizers are washed away from pipes and heads. Fertilizer solutions accumulated on leaves are also washed off.

- A pressure test should be conducted before covering the pipes in fixed and semi-fixed irrigation systems.

- In fixed and semi-fixed systems, pipes are buried in the ground to a minimum depth of 50cm where winters are mild, and to a minimum depth of 80cm where winters are heavy.

- Proper grounding is a must, if the motor is electrically driven.

- Attention should be paid to power lines in order not to touch them when carrying pipes.

- The system is first operated at a lower flow rate, filling laterals and intermediate pipes with water, and then the pipeline should be washed by opening the pipe stopper for a short while.

- A filter should be installed at pump suction pipe for keeping foreign materials away and nozzles unclogged.

- Rotation of laterals must be planned.

- For optimum sprinkle distribution, laterals should be well positioned according to the wind direction.

- Rubber grease or similar materials should be used on pipes and sprinkler heads for lubrication.

- In fixed systems, pipelines should be discharged at season ends.

Although pump requirements vary depending on desired shooting range, flow rate and environmental effects, we would suggest following horsepower for our three different sizes of irrigation sprinklers.

- DuCaR JET35/35T : Min 10 HP

- DuCaR JET50 : Min 15 HP

- DuCaR JET70 : Min 30 HP

For detailed FREE irrigation design, you can submit your land's properties such as dimensions, distance from the water source and other environmental factors.

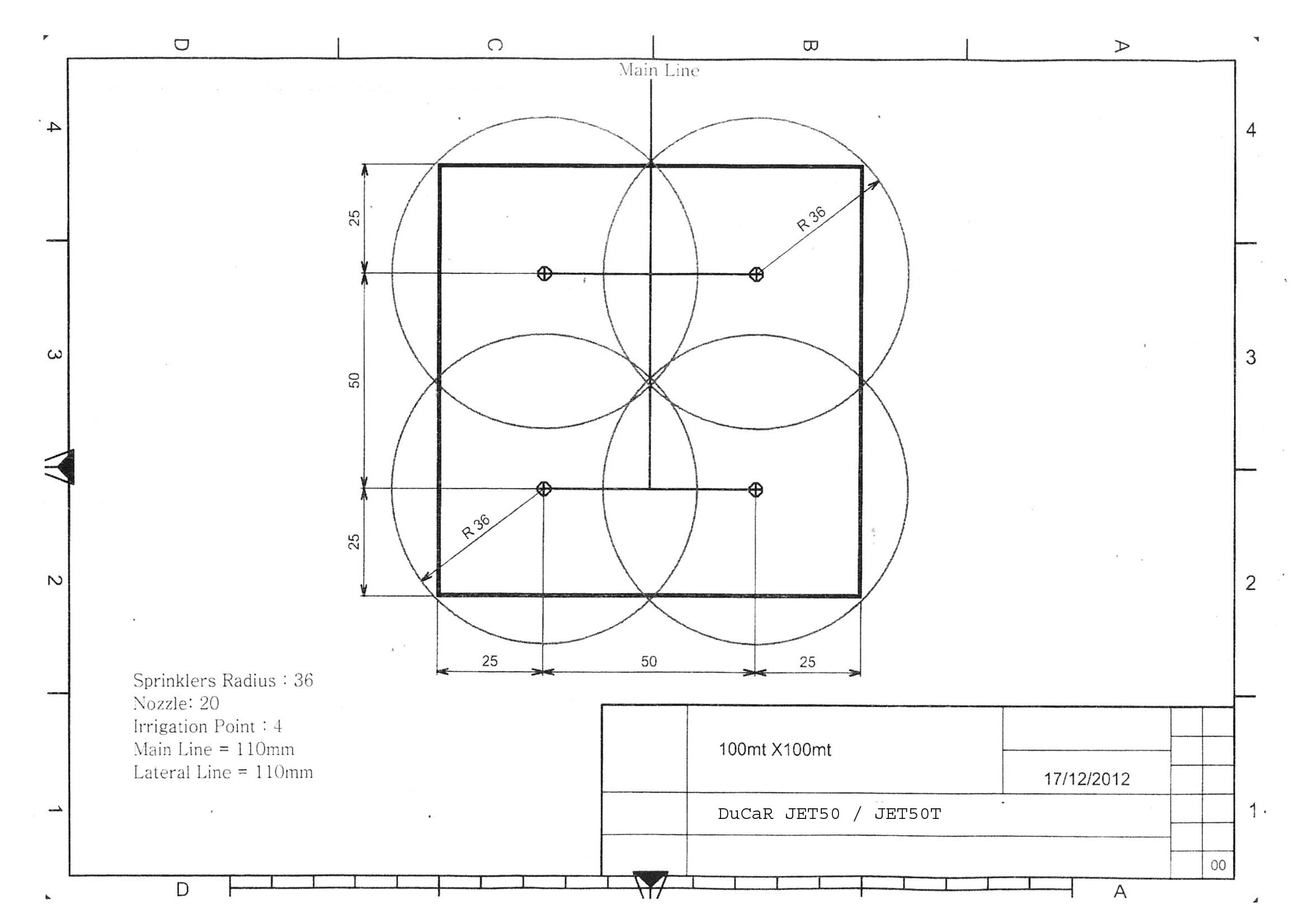

We would suggest you to use DucaR JET50 or JET70 as the most suitable sprinkler types. In this case, we will design our irrigation solution based on 4 DuCaR JET50 as shown below.

If you wish to irrigate the whole land at a time, then four of the sprinklers have to be run simultaneously on a pipe line with minimum 110m radius. However if you do not have enough water pressure, you may choose partial irrigation.

In this method, you will need to use our four 4-legged stands coming with quick coupling. Yet the required total number of sprinklers can be reduced from 4 to 2 and you can reduce your cost! DuCaR 4 legged stands with quick coupling, makes installing the sprinkler head so easy and quick. However all the stands have to be connected to the pipe line with a valve, so you can irrigate half of the land for desired time by switching off the valves of those two stands. The sprinkler heads can easily and quickly be moved to the other two stands. Then by switching on the valves of those stands, the other half of the land is irrigated with no extra cost!

Each sprinkler head on our site has a published performance chart from the manufacturer stating how much flow and pressure it takes to operate each size sprinkler and lists the performance data of the sprinkler at a chosen flow rate and pressure setting. Most sprinklers will operate in a wide range of flows by simply adjusting the nozzle size to match the flow capability that your well or pump provides. Pressure requirements vary and typically as pressure is increased, the performance pattern of the sprinkler will increase. Your servicing pump dealer should be able to tell you what your well or pump's capability is and then you can match your pump's capability to a sprinkler performance chart of your choosing.