ARMAS SUCTION FILTER

APPLICATIONS

- Agricultural applications

FEATURES

- Protection of pumps

- Low head loss

- Automatic self-cleaning system

- Uninterrupted filtration during automatic self-cleaning

- Low maintenance costs

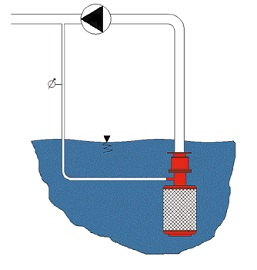

Suction filter is designed to protect the pumps from debris and foreign matters. It is generally used in water sources containing algae, debris, and other heavy wastes. It is connected to pump suction and submerged into water (river, lake, reservoir, etc.)

|

OPERATING PRINCIPLE

Water is sucked by the pump passes through the strainer and debris is kept outside by the stainless steel screen. Rotating nozzles are fed with water taken from the pump exit. Water jets sprayed from the nozzles blow away the debris collected on the outer surface of the screen and thus the filter is cleaned.

Thus the pump is protected against clogging and failures. Pump efficiency increases and maintenance costs decrease.

- Minimum working pressure: 1.5 bar (22 psi)

- Suggested working pressure: 3-4 bar

- By-pass flow rate: 4 m3/h (3"-4")

- Electrostatic coated body

- Rotating Nozzles

- Flange type Connection

- Electrostatic applied and oven-cured zinc-phosphate coating for anti-corrosion protection

- Available models: 4", 6", 8"

|

![]() Download Product Catalogue

Download Product Catalogue